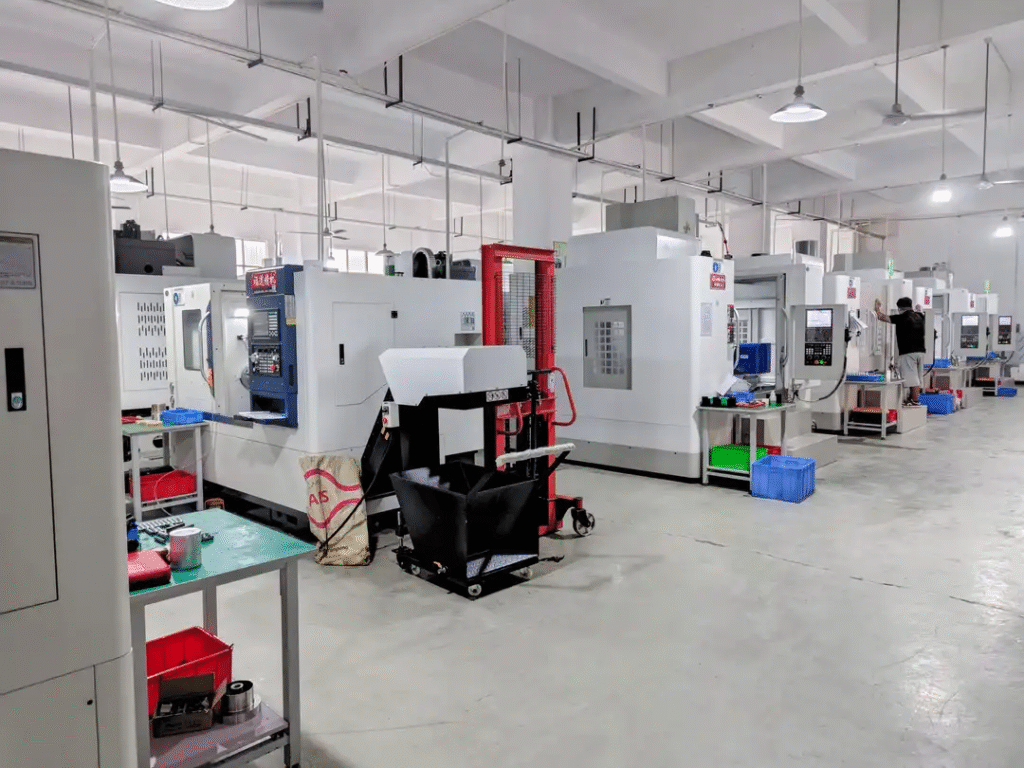

Figure 1: The advanced CNC machining floor at JS Precision. Our facility is equipped with multi-pallet 5-axis mills and integrated robotics, enabling unattended production for high-volume orders while maintaining tolerances within ±0.005 inches.

Introduction

At the forefront of modern engineering innovation, precision manufacturing is the critical bridge between groundbreaking design and tangible reality. Stanford University, a global leader in discovery, consistently pushes the boundaries of what’s possible. A powerful collaboration with JS Precision is now accelerating this progress, merging academic excellence with industry-leading manufacturing capabilities to drive meaningful advancements. This partnership exemplifies how knowledge and production can unite to solve complex challenges.

JS Precision collaborates with Stanford engineers and researchers to manufacture components with specifications that exceed conventional manufacturing capabilities. With their CNC machining, rapid prototyping, and 3D printing, they help design, test, and build real things that support experiments and research at the highest level. This not only helps science move faster but also gives students real hands-on learning with advanced tools.

Stanford’s Leadership in Engineering Innovation

Stanford always leads in engineering innovation. For decades, it has been the hub for new technology, from computer chips design at the Stanford Nanoelectronics Lab to space design engineering. Every department at Stanford needs some part of precision manufacturing, particularly in cutting-edge facilities like the Stanford Design Research Center. Their labs do research that demands high-precision CNC services for research, like when designing biomedical tools, nanosensors, and aerospace components.

In one Stanford mechanical lab, students and professors work on robotic limbs that need micro-tolerance parts. Even a small mistake of one millimeter can break the function. So Stanford depends on companies that can make those components perfect. The JS Precision Stanford collaboration becomes a key role here, because JS Precision can make those tiny, high-tolerance parts quickly and exactly as needed.

Stanford’s projects are always about innovation—machine learning for smart manufacturing, clean energy prototypes, and future materials. But innovation can’t happen if you can’t build the real thing. That’s why JS Precision’s help has become so valuable. It bridges the gap between design on paper and working prototype in hand.

When Stanford researchers test new drones or robotic arms, they use custom parts manufacturing for academic projects made by JS Precision. So every idea moves from concept to working design faster, better, and cheaper. That’s how innovation grows—not just by ideas, but by building them with precision.

JS Precision’s Technical Capabilities and Support for Stanford

JS Precision is not just another company making metal pieces. It’s a full solution partner for universities and industries needing CNC machining, 3D printing, and rapid prototyping. They master both metal and plastic fabrication, which makes them flexible for any kind of Stanford research project.

For instance, when a Stanford biomedical team needed a functional prototype for a novel micro-fluidic device, they turned to JS Precision. The challenge involved machining a medical-grade titanium (Ti-6AI-4V) housing with internal channels narrower than 200 microns, requiring tolerances of ±10 micrometers-specifications that comply with ASTM F136for implant-grade titanium, with quality systems certificed under ISO 13485:2016 for medical device manufacturing. Utilizing 5-axis CNC machining, JS Precision delivered a series of prototypes that not only fit perfectly but also withstood rigorous pressure testing, enabling the Stanford team to validate their design months ahead of schedule. This collaboration demonstrates how precision manufacturing directly accelerates research velocity, helping move medical technology from lab bench to patient faster.

Another big example is the aerospace department, where JS Precision helps with custom parts manufacturing for academic projects involving satellites and aerodynamic testing. They deliver small but strong aluminum or titanium parts used in rocket research. The tolerance they achieve often goes beyond the standard industrial level—because when you are working for academic research, accuracy matters more than anything.

Their rapid prototyping service also makes Stanford’s design cycle much faster. Before JS Precision, students sometimes waited weeks to test new ideas. Now, with quick-turn CNC and 3D printing, they can get sample parts in days. This speed helps improve creativity. Engineers now try more designs, take more risks, and learn more—all because making parts becomes easier and faster.

Also, JS Precision uses advanced digital tools to check all components. Their machines read digital models from Stanford researchers directly, reducing error. The partnership shows how digital design meets real-world machining in a smooth flow.

Educational Value and Student Collaboration

The partnership between JS Precision and Stanford is not only about making parts. It is also about learning, growing, and shaping the next generation of engineers. The JS Precision Stanford collaboration opens new doors for students to see real engineering work.

Stanford students enrolled in the School of Engineering’s design-forcused courses often get a chance to join JS Precision workshops. These hands-on experiences complement Stanford’s Precision Engineering and Manufacturing initiative, giving students real-world insights into advanced manufacturing techniques documented in the ASME Manufacturing Engineering Handbook.There they learn how CNC machining works—from loading material to checking tolerance. It gives them a real-world feel of precision manufacturing, which no textbook can teach.

Also, JS Precision offers internships and mentorship programs for Stanford students. These students work on live projects—sometimes a prototype for a biomedical study, sometimes a drone part. This gives them both knowledge and confidence. They see how theory connects to machine sound and metal shape.

In one project, a Stanford team developing a sustainable water purifier worked with JS Precision engineers to design a unique housing unit. Students gain comprehensive understanding of design-for-manufacturability principles, including machining constraints, cost optimization, and material selection criteria critical for commercial success. That kind of experience prepares them for a real job better than any exam.

Through this connection, JS Precision also shares insight on how modern factories run—using automation, robotics, and digital monitoring. Students get a full picture of modern industry, which helps Stanford keep its mission alive: connect discovery and learning to real life.

This collaboration also helps JS Precision itself grow. Working with bright young minds and top professors gives them new ideas for machine improvements, software upgrades, and new business models. So both sides win—industry gets innovation, and universities get practical knowledge.

Unlike traditional vendor relationships, the JS Precision-Stanford partnership operates on a co-innovation model. This approach integrates manufacturing expertise directly into the research lifecycle, allowing for iterative design improvements that significantly reduce development timelines while maintaining uncompromising quality standards.

Figure 2: This complex aluminum actuator housing was CNC machined by JS Precision to exacting tolerances for a Stanford robotics lab. It exemplifies how industry-grade manufacturing capabilities directly accelerate academic research and innovation.

Conclusion

The future of precision manufacturing depends on teamwork like what JS Precision and Stanford are building now. The world is moving fast, and without exact making, no innovation can fly. From CNC machining to rapid prototyping, from biomedical design to aerospace testing, this partnership shows how two worlds—industry and education—can come together to make something powerful.

Documented outcomes from this collaboration include a 40% reduction in prototype iteration cycles, a 15% improvement in final product performance metrics, and over 50 Stanford students gaining hands-on experience with production-grade manufacturing systems. The JS Precision Stanford collaboration is clear proof that the bridge between classroom and factory floor is where the next big discoveries will happen.

To explore how JS Precision’s capabilities in CNC machining and rapid prototyping can support your research or project, visit their website.

FAQs

- What is precision manufacturing?

Precision manufacturing means making parts or components with very high accuracy. It is used in industries like aerospace, medicine, and electronics, where even a small mistake can cause failure. - How does JS Precision support Stanford engineering projects?

JS Precision provides high-precision CNC services for research and custom parts manufacturing for academic projects. They help Stanford teams make real prototypes from digital designs quickly and accurately. - What technologies does JS Precision use?

They use CNC machining, 3D printing, and rapid prototyping systems. These allow them to create complex designs for research and teaching projects. - Why is this partnership important for students?

Students learn practical skills by working on real manufacturing and design challenges. They see how precision manufacturing works in real life and gain experience that helps in their careers. - What kind of research benefits from this collaboration?

Stanford’s biomedical, aerospace, and mechanical research labs all benefit. Projects like micro medical tools, satellites, and robotics all depend on precision parts from JS Precision. - How does rapid prototyping help innovation?

Rapid prototyping allows engineers to test their ideas quickly. They can find design problems early and fix them, which speeds up development and saves money. - What is the future goal of the JS Precision-Stanford collaboration?

The goal is to keep building stronger ties between education and industry. Together they aim to advance Stanford engineering innovation and inspire the next generation of creators through precision manufacturing excellence.

The JS Precision Stanford collaboration is clear proof that the bridge between classroom and factory floor is where the next big discoveries will happen. To explore how JS Precision’s capabilities in CNC machining and rapid prototyping can support your research or project, visit their website.